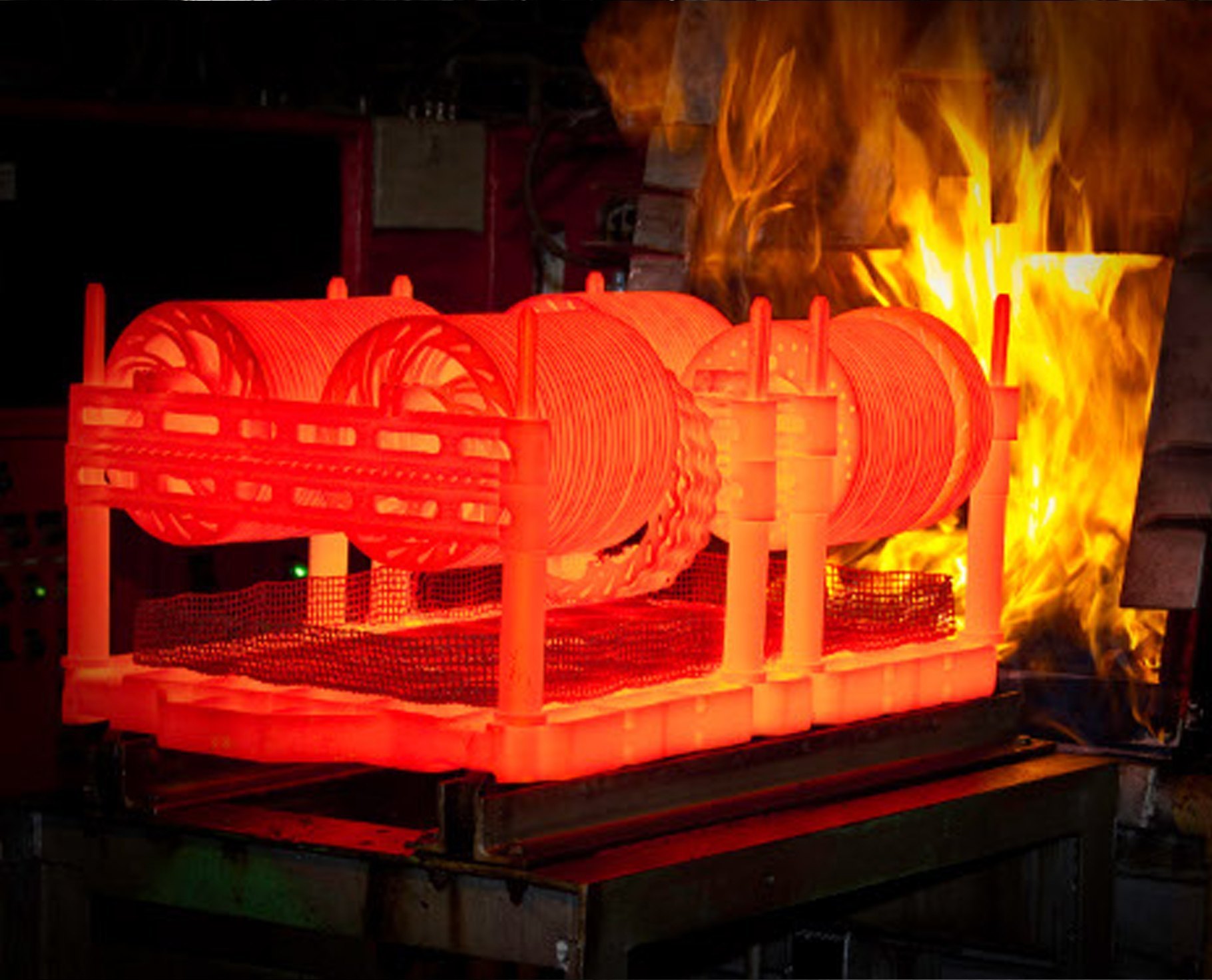

Stress Reliving

A heat treatment technique called "stress relieving" is intended to lessen internal stresses that form in metal parts during cold working, welding, casting, or machining. This procedure reduces the possibility of distortion, cracking, and early failure in service by heating the material to a precise temperature below the transformation range and then gradually cooling it. Our stress-relieving services are perfect for precision-machined parts, welded assemblies, and structural parts because they increase dimensional stability and improve overall performance. For reliable, superior results, we guarantee even heating and regulated cooling.